The Austrian company INGENIA specializes in the design of galvanizing lines.

For more than thirteen years, INGENIA has been designing and building not only safe and environment-friendly technological equipment for hot dip galvanizing lines, but also turnkey plants – from green field to finished production bay.

The implementation of individual projects for galvanizing plants again and again confirms the need for an integrated approach. This is due to the different needs of each customer, thus, excluding the possibility of INGENIA applying some kind of average standard. On the contrary, tailor-made and demand-specific logistic solutions are the basis for the commercial success of galvanizing plants of INGENIA customers.

Drying furnaces (INGENIA)

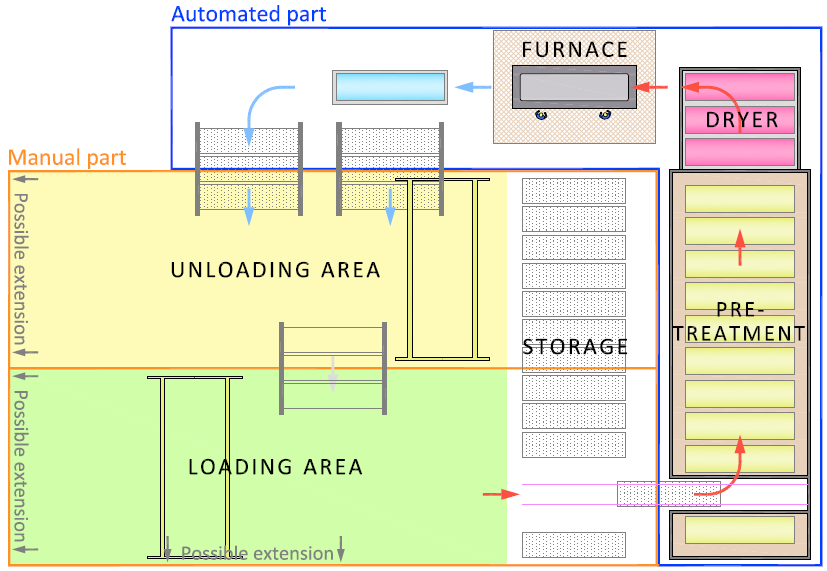

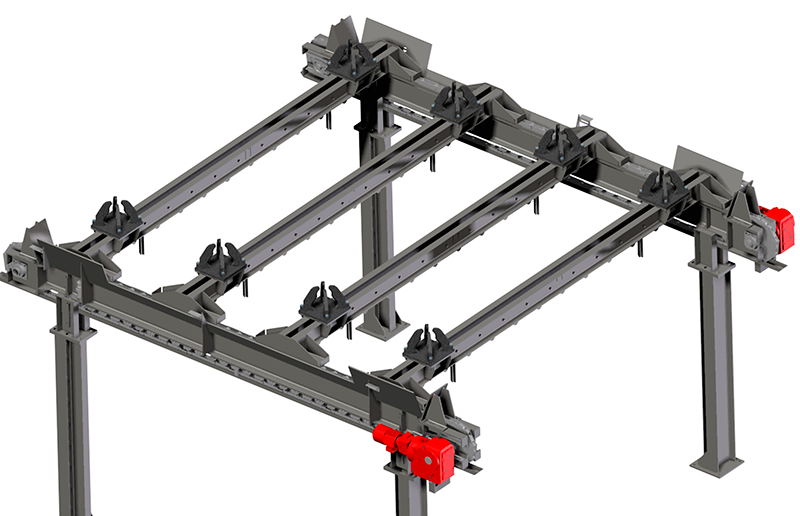

Logistic Type BASIC (INGENIA)

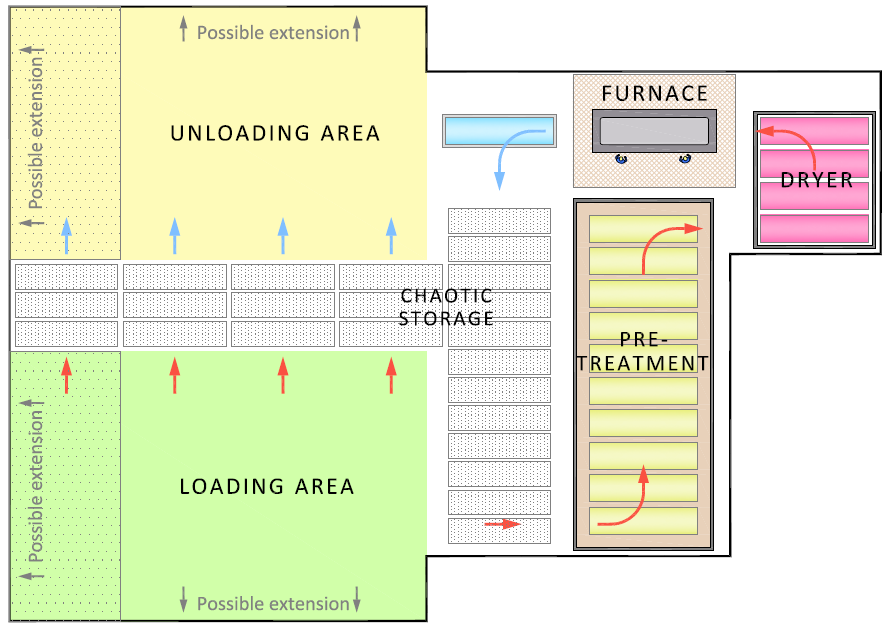

Logistic Type SEMI (INGENIA)

Logistic Type PROFESSIONAL (INGENIA)

Single Centrifuge (INGENIA)

Pre-treatment technology (INGENIA)

Galvanising furnaces (INGENIA)

Galvanising furnace flue gas capture and dedusting (INGENIA)

Turnkey plants (INGENIA)

Chain hoists (INGENIA)

Rope hoists (INGENIA)

Lifting-lowering stations (INGENIA)

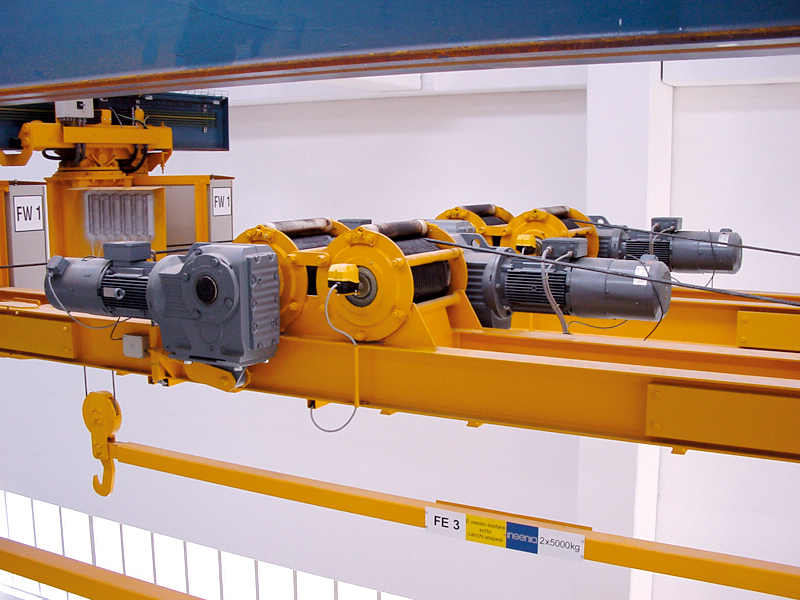

Bridge cranes (INGENIA)

Claw & Toggle – the Original (INGENIA)

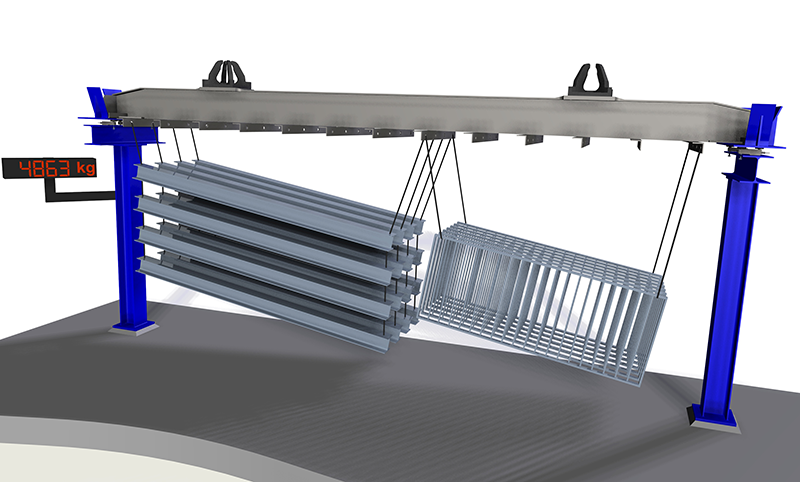

Lifting beams (INGENIA)

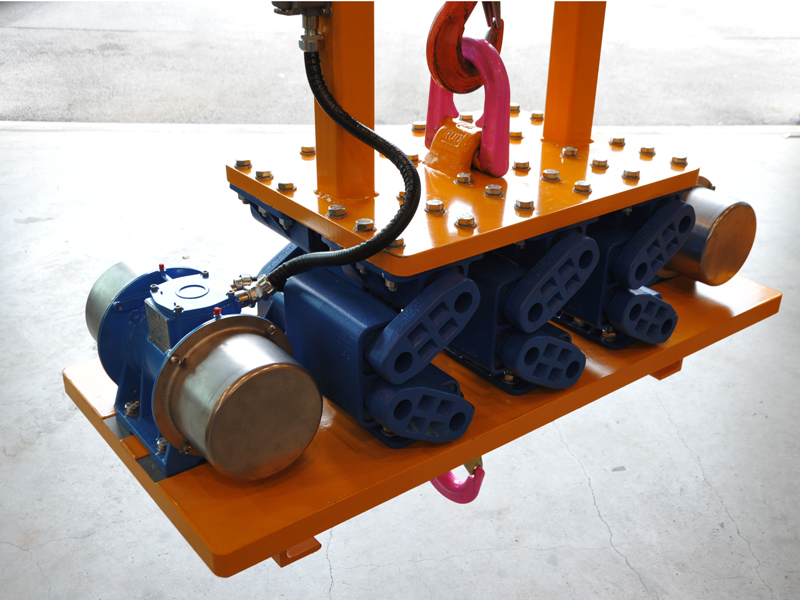

Vibrators (INGENIA)

Chain conveyors (INGENIA)

Calibrated weighing systems (INGENIA)

Monorail systems (INGENIA)

Control systems (INGENIA)