Magnesia products

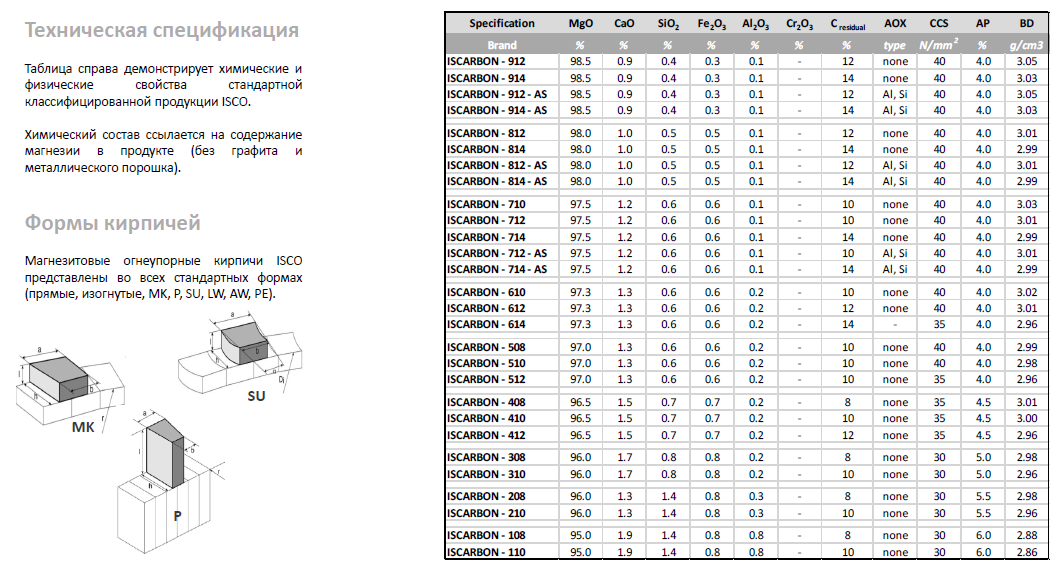

The combination of a wide range of magnesia grades with different qualities and amounts of added graphite, as well as a variety of additives in the form of Al and Si metal powders, MgO micro powder and others, provides a wide range of finished products. The ISCO standard concept uses 9 different combinations of magnesia grades (ranging from 1 being standard burned magnesia DBM95, to 9, top quality fused magnesia with MgO content of over 98.5%). We use graphite with a carbon content from 94% to 98% and add it in quantities of 5% – 20% (weight % of the brick). If certain production processes of our customers, for example, have a high oxidation potential, then other additives can be used. These additives are usually metal powders. If extremely high densities are required, micro powder additives can be applied. The diagram on the right shows the nomenclature we use to classify our wide range of products.

Product application

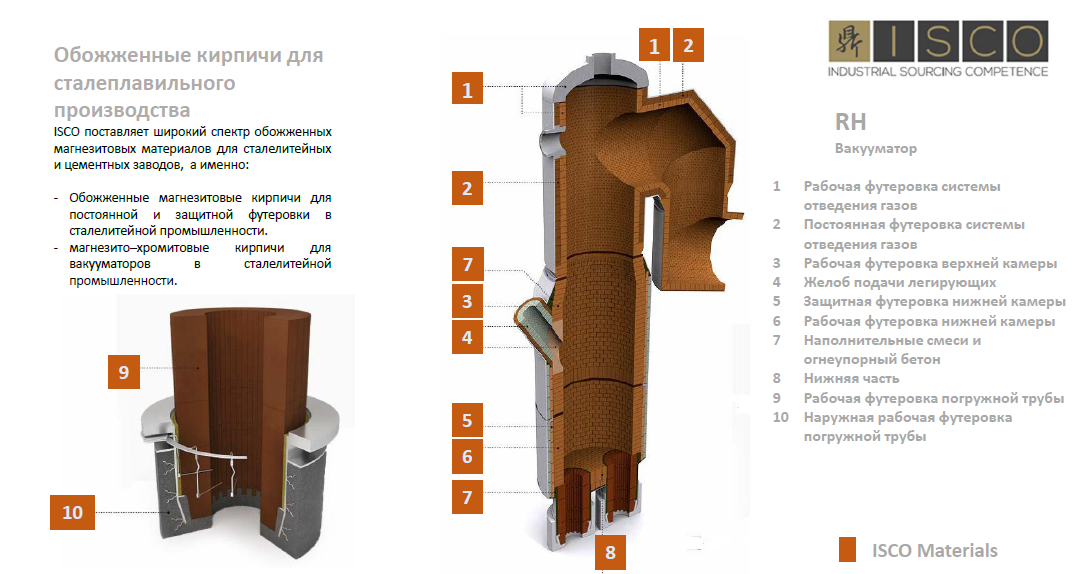

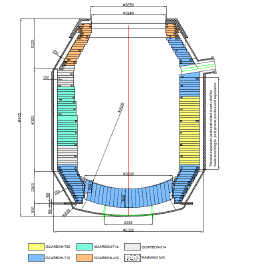

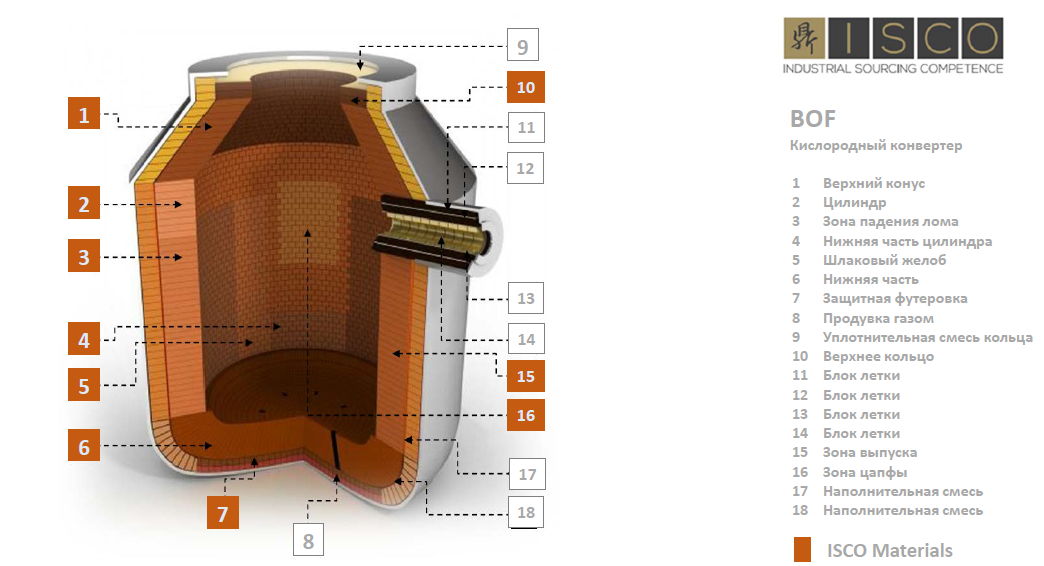

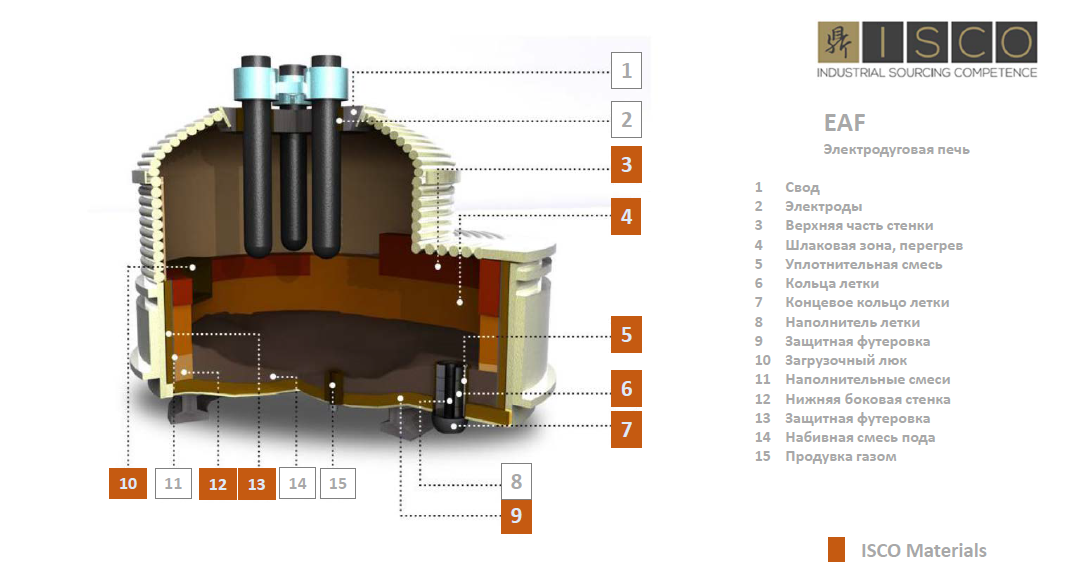

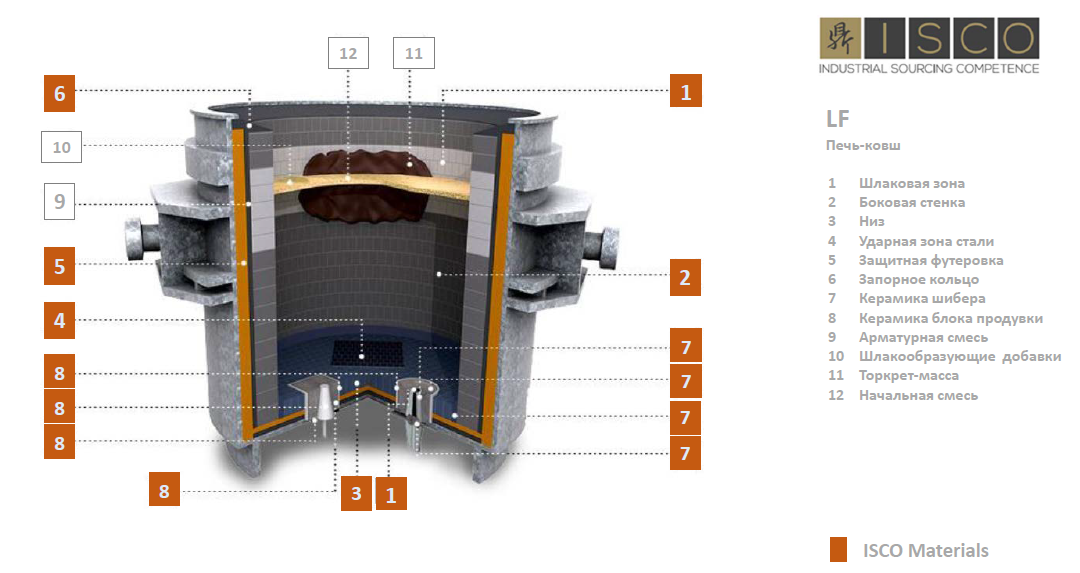

The schematic diagrams on the slides below show the typical use of ISCARBON refractory items in various steelmaking units.

The table on the right shows some of ISCO standard grades and a typical lining concept.

In fact, every steel plant should take into account the corresponding parameters. Therefore, to find the ideal lining solution, steel plant technicians need to consult with our refractory experts.

Обожженные магнезитовые, магнезито-хромитовые и магнезито-шпинельные огнеупорные кирпичи