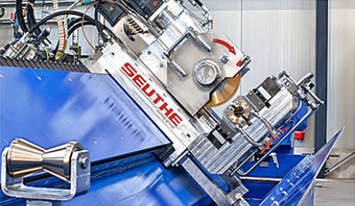

Немецкая компания SEUTHE GmbH с 1899 производит оборудование для изготовления сварных труб и профилей, а также открытых профилей из стали и нержавеющей стали. В настоящее время SEUTHE предлагает современные трубосварочные агрегаты и профильные станы и линии – как стандартные, так и разработанные и сконструированные индивидуально в соответствии с запросами заказчиков. С 2010 года, компания SEUTHE входит в группу компаний ASMAG Group.

Процесс изготовления сварных труб обычно состоит из следующих этапов: подготовка полосы, накопление полосы, формовка, сварка, правка/ калибровка, резка, дальнейшая обработка на линии отделки, складирование, обвязывание и упаковка.

Для всех вышеперечисленных операций компания SEUTHE конструирует и производит соответствующие машины. Оборудование может поставляться как отдельно, так и комплексной линией для производства готовых труб из листа. SEUTHE производит оборудование для производства труб с минимальным диаметром 4,7 мм, максимальным диаметром 406 мм, с толщиной стенки 0,5-16 мм из стали, нержавеющей стали, алюминия, латуни, меди и медных сплавов.

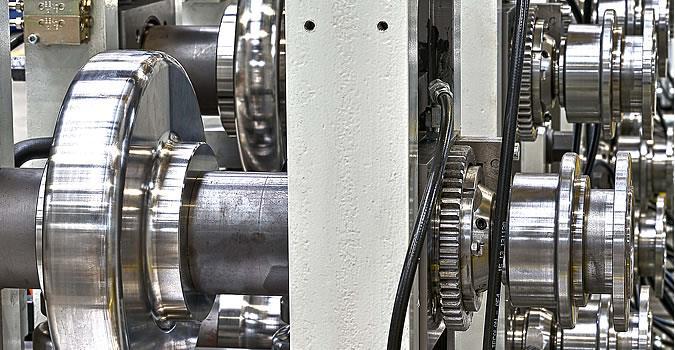

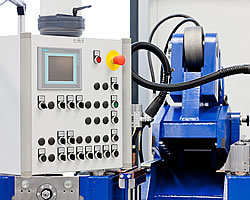

Классические трубоэлектросварочные агрегаты (SEUTHE)

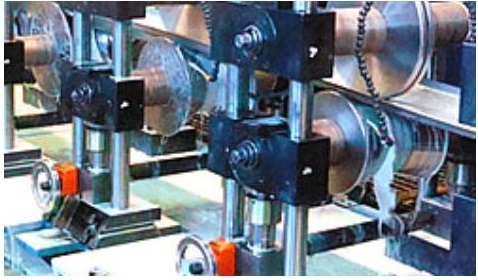

Станы с технологией клетевой формовки CTA® (Central Tool Adjustment) (SEUTHE)

Станы с технологией клетевой формовки FCF® (Flexible Cold Forming) (SEUTHE)

Трубоэлектросварочные станы для нержавеющей стали (SEUTHE)

Профильные станы (SEUTHE)

Машина для резки и сварки концов полосы (SEUTHE)

Устройство для обработки поперечного шва (SEUTHE)

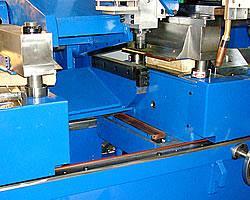

Устройство для удаление грата с внешней и внутренней поверхности трубы (SEUTHE)

Летучие пилы (SEUTHE)